Samsung to Replace Silicon with Glass in Chip Production

Samsung Electronics plans to switch to glass intermediate layers in chip production by 2028, abandoning traditional silicon. According to the manufacturer, this will increase the performance of processors, especially for AI tasks, and reduce the cost of their production.

Samsung Electronics plans to change the way it makes chips by replacing silicon with glass in key components by 2028. The company says the move could improve chip efficiency and reduce manufacturing costs, which is especially important for processors used in artificial intelligence systems.

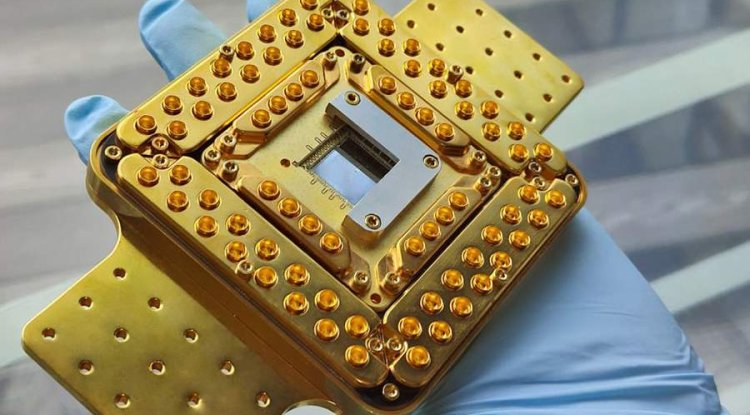

Chips currently use silicon interlayers that connect various components, including HBM memory and graphics processors. However, silicon has limitations — it is more expensive to produce and less flexible to process than glass. Glass layers, Samsung says, allow for thinner, more complex circuits, conduct heat better, and warp less when heated.

The company uses an unconventional approach, cutting glass into small blocks of less than 100x100 mm, while other manufacturers work with large-format sheets. This can improve manufacturing accuracy and reduce the percentage of defects.

If the transition to glass components is successful, it could impact the development of the semiconductor industry, especially in the segment of high-performance chips for AI and data centers. The first mass solutions based on the new technology are expected to appear by 2028.

Share

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0

![Transfer/ Postings Senior Superintendent Police Hyderabad [Notifications]](https://pakweb.pro/uploads/images/202402/image_100x75_65d7bb0f85d5f.jpg)

![Amazing Text Animation Effect In CSS - [CODE]](https://pakweb.pro/uploads/images/202402/image_100x75_65d79dabc193a.jpg)